Unilift System Technology

The new generation of sectional door automation systems

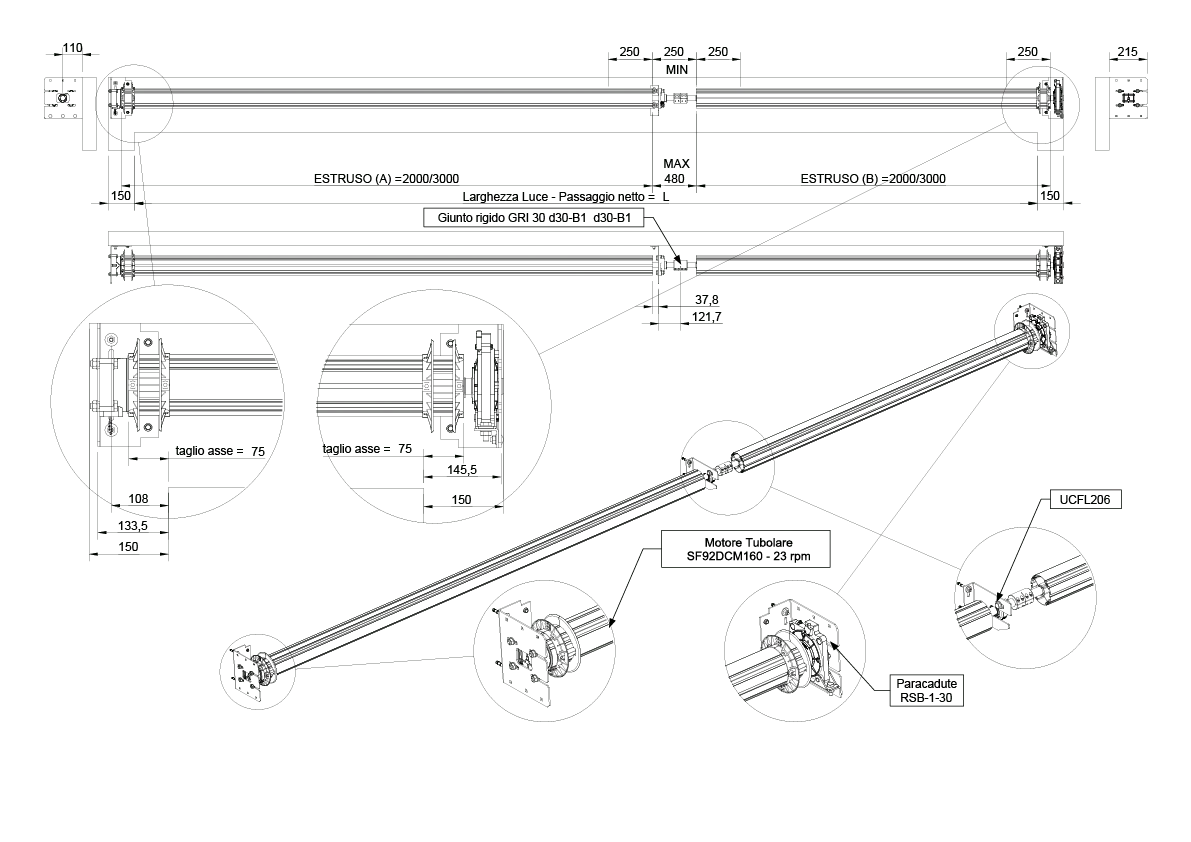

The MTB system represents a complete automation solution for industrial and commercial sectional doors up to 6 × 5 meters. This drawing illustrates the system architecture with its dimensions.

- Drive shafts: Two extruded aluminum profiles (EXTRUSION A and B) of 2000 or 3000 mm (modifiable), spaced according to the passage width (L), with a minimum lateral clearance of 150 mm

- Motorization: Tubular motor SF92DCM (200 Nm at 18 rpm or 160 Nm at 23 rpm) positioned on the sides with integrated inverter, allowing up to 334 kg load capacity

- Anti-fall safety: RSB-1-30 safety device with different protection levels (braking torque 365 Nm, anti-fall torque 1444 Nm) mounted on a dedicated shaft

- Transmission: Double-belt system with adjustable tension, ensuring excellent stability and durability

- Intermediate bearing: UCFL 206 support for large-width doors, ensuring axial alignment

- Dimensional specifications: Enlarged details show the exact footprint: shaft cut = 75 mm at the ends, with fixings from 30 to 108 mm depending on installation.

- The central space, ranging from (MIN 250 MAX 480), houses the rigid coupling GRI 30 for connecting the two 30 mm shafts

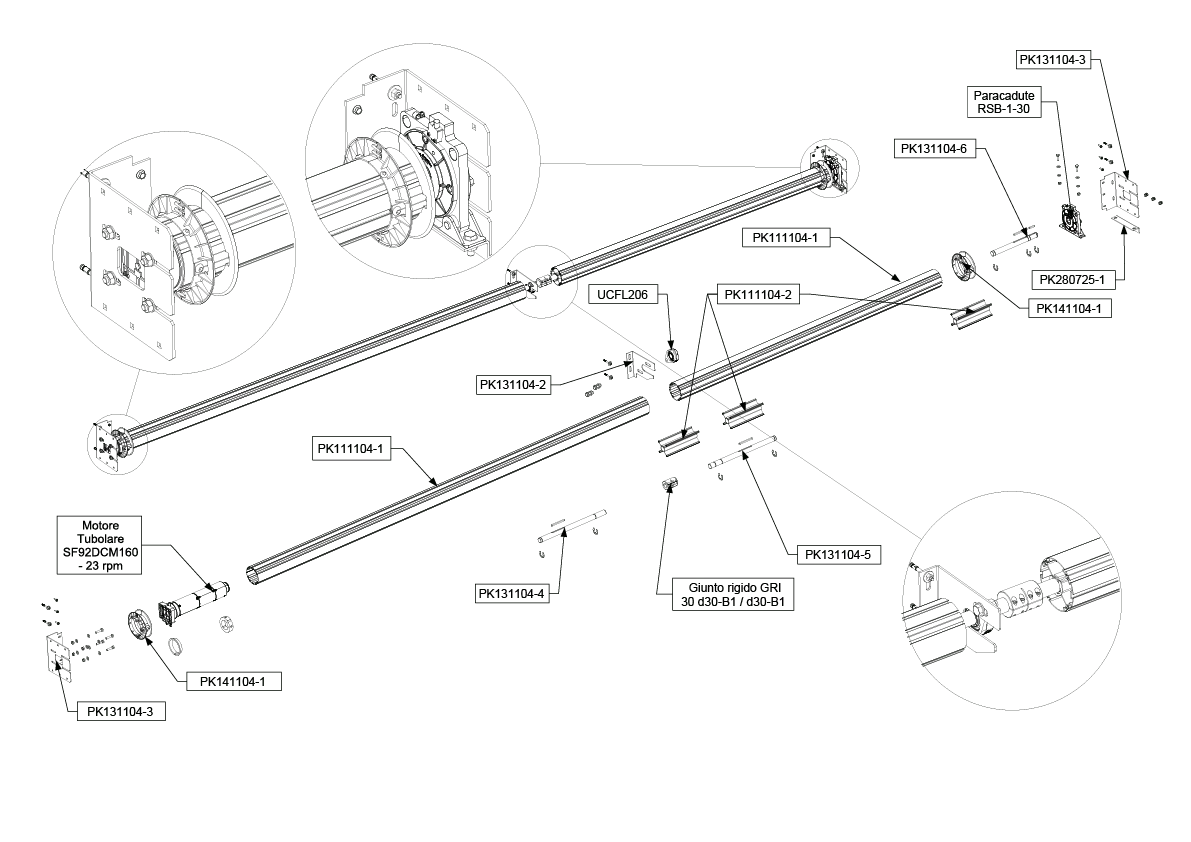

This exploded view shows the technical composition of the MTB system, revealing its modularity

Motor unit (left):

- Tubular motor SF92-DCM160 with integrated inverter

- Coupling adapters 97 for connection to axial profiles

- Fixing system with shaft extractor allowing disassembly without removing the entire system

Transmission train:

- PK111104-1: Aluminum extruded shaft profile

- PK131104-2: Intermediate bracket in galvanized steel

- Rigid coupling GRI 30 (d30-B1): Rigid joint ensuring torque transmission between both shafts

- UCFL 206: Self-aligning support mounted on intermediate bracket for intermediate shafts

Safety module (right):

- RSB-1-30 safety device inserted on shaft PK131104-6 and mounted on angle PK280725-1 screwed to reversible bracket PK131104-3, fixed by radial ring M24 (UNI 7434)

- Safety foot PK280725-1 with M8 class 8.8 bolts

Lifting systems:

- Nylon alignment flange

- 30×2 belts fixed with locking plates and fully threaded screws on recessed M8 nuts, locked with flanged M8 nuts

- 4 mm sealed cables with openable eyebolts for belt fastening

Durability: 100,000 cycles with a maximum of 11 cycles/hour

Designed according to EN 13241 / 12604 / 12453, in compliance with CPR 305/2011 and product directives (see manual)

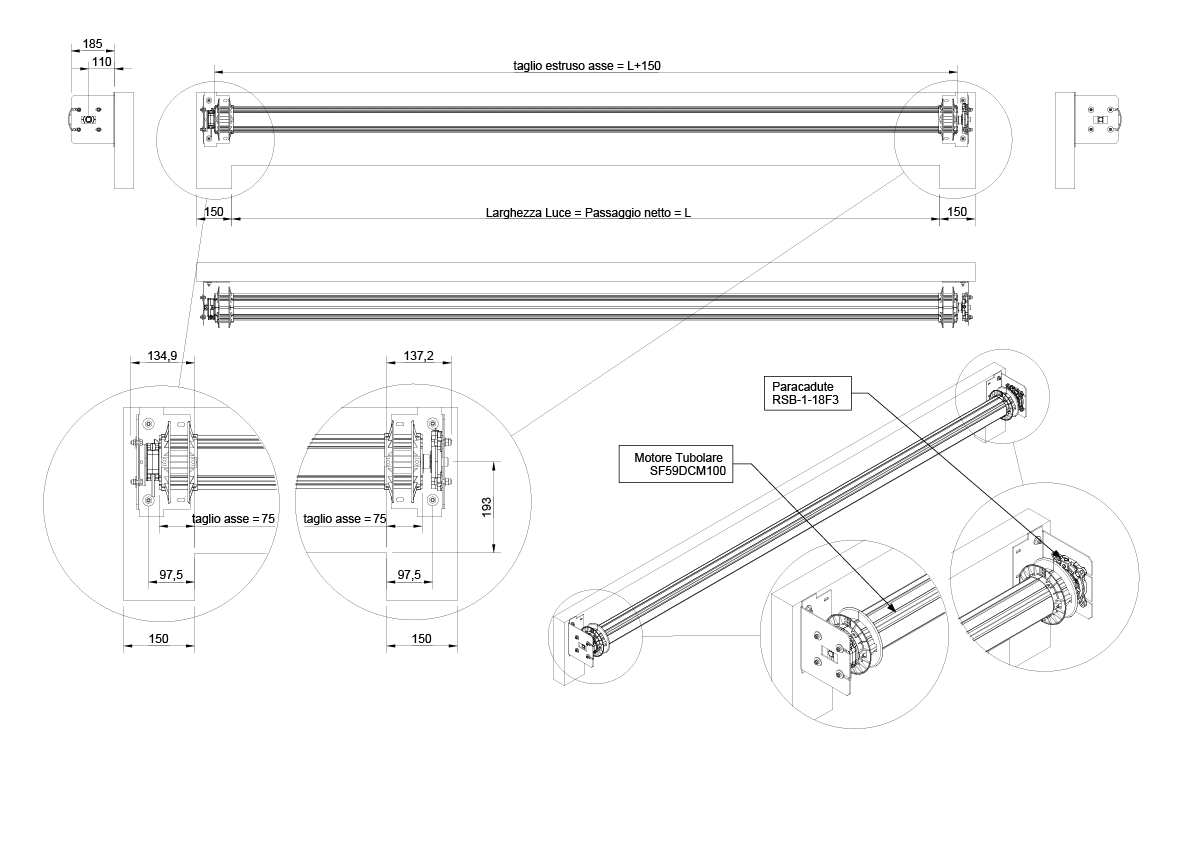

The MTB-LB is the compact version optimized for small-scale applications up to 3.5×3.5 meters.

Simplified architecture:

- Monoblock shaft: Single shaft profile (extruded shaft length = L + 150) eliminating the intermediate joint

- Light motorization: Tubular motor SF59-DCM100, lifting up to 146 kg

- Dedicated safety brake: RSB-1-18F3 (braking torque 137 Nm)

- Reduced footprint: Lateral space including guides of 150 mm, allowing flush installation in confined spaces

Technical details of supports:

- The side enlargements show a shaft cut of 75 mm with a total footprint of 150 mm.

- The bottom-right drawing shows the SF59-DCM100 Nm motor with its reversible bracket and the 18E/130 Nm safety brake, both using the same bracket.

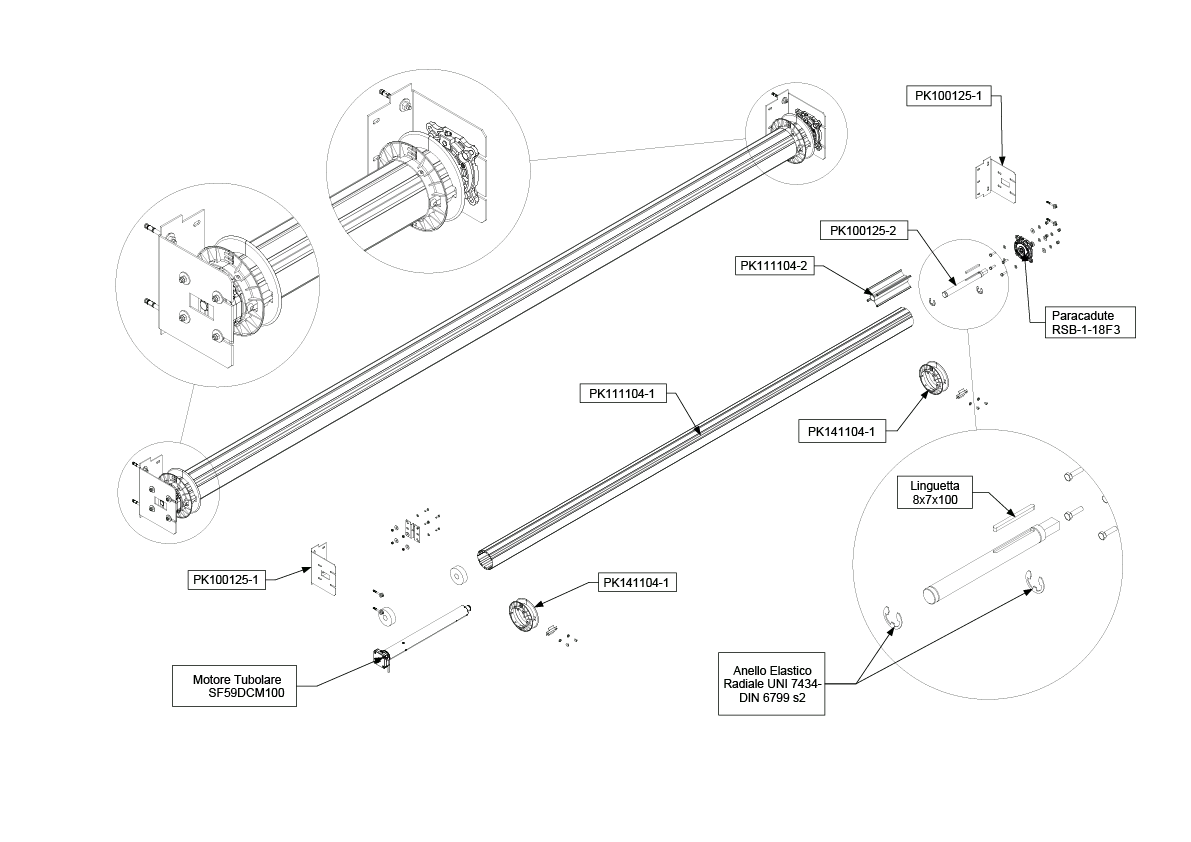

Exploded view of the MTB-LB system showing its technical composition

Integrated motor module (left):

- Reversible bracket MTB-LB PK100125-1 suitable for mounting both the motor and the safety brake

- Tubular motor SF59-DCM100 with 97 adapter

- Fixing with 4 TETF M6×20 screws, M6×24 washers and self-locking nuts

Axial transmission:

- PK111104-1: Extruded aluminum shaft profile, length = L (door width)

- PK111104-2: Extruded aluminum core profile designed to house 30 mm shaft and safety device

- Adapters 97 for motor and limit switch

Safety group (right):

- Reversible bracket PK100125-1 housing the RSB-1-18F3 safety brake

- Safety brake 18EF3 with radial ring M24 (UNI 7434)

- Tongue with key 8×7×100 for torque transmission

- Radial retaining ring M24 (UNI 7434) securing the 30 mm shaft

Simplified lifting system:

- Nylon alignment flange (4 units) fixed with full-thread M8 screws on recessed M8 nuts and locked with flanged M8 nuts

- Belt locking plates

- 30×2 belts with openable shackles for cable-to-belt connection

Durability: 100,000 cycles with a maximum of 11 cycles/hour

Designed according to EN 13241 / 12604 / 12453, in compliance with CPR 305/2011 and product directives (see manual)

Product Advantages

TECHNOLOGY & CIRCULAR DESIGN ADVANTAGES

- ESG Compliance & Eco-design

OPERATIONAL

ADVANTAGES

- “Plug-and-play” Installation = Optimized Time-to-value

- Reduced Maintenance Costs (Optimized TCO)

- Integrated Safety

LOGISTICS

ADVANTAGES

- Inventory Optimization (Reduced TCO)

- Export-friendly